A efficient auto-weighing packaging machine is a vital asset for any business that handles granular materials. These machines offer precise weighing capabilities, ensuring uniformity in every package produced. By integrating automated weighing with packaging processes, these machines optimize production speed and reduce manual labor, leading to higher productivity.

- Common applications for auto-weighing packaging machines include the distribution of food products, chemicals, pharmaceuticals, and industrial materials.

- The incorporation of a computerized control system allows for easy programming of target weights and adjustments to meet specific production requirements.

- Advanced auto-weighing machines often feature integrated quality control systems that detect irregularities in weight and trigger error messages to ensure packaging accuracy.

Automated Bagging System

A fully automatic/automated/self-operating bagging system is a sophisticated/advanced/cutting-edge piece of equipment/machinery/technology designed to efficiently/rapidly/seamlessly pack products/goods/items into bags. This system/process/solution typically incorporates/utilizes/employs a series/chain/sequence of mechanisms/components/parts to accomplish/achieve/execute the entire bagging process automatically/without human intervention/remotely. From feeding/dispensing/delivering material/products/items into bags to sealing/closing/fastening them securely, the system operates/functions/works with precision/accuracy/consistency.

- Benefits/Advantages/Features of a fully automatic bagging system include:

- Increased Efficiency/Higher Production Rates/Reduced Labor Costs

- Improved Accuracy/Minimized Errors/Consistent Bag Sizes

- Enhanced Safety/Reduced Risk of Accidents/Worker Protection

Automated Bag Sealing Machine

A digital bag sealing machine is an indispensable tool for companies that deal with packaging products in bags. These machines seamlessly seal bags using ultrasonic technology, providing a strong closure to preserve the contents. Diverse types of bag materials, including plastic, paper, and film, can be joined with these machines, providing a high-quality finish.

- Benefits of using a digital bag sealing machine include improved productivity, cost savings, and enhanced product safety.

- Additionally, these machines are user-friendly and can be configured to meet specific sealing requirements.

Accurate Weighing and Packaging Systems

In the realm of manufacturing, achieving exact weighing and bagging is paramount for consistency. Our state-of-the-art Precision Weighing and Bagging Solution is designed to enhance these critical processes, ensuring that your products are filled with perfect accuracy.

- Equipped with a advanced weighing system, our solution ensures consistent and reliable results every time.

- Integrated packaging processes eliminate manual intervention, improving efficiency while ensuring the highest standards of accuracy.

- Our solution is adaptable to various needs, allowing you to adjust settings based on your goods and packaging needs.

By utilizing our Precision Weighing and Bagging Solution, you can improve your operations, reduce waste, and deliver products that meet the exacting quality standards.

Streamlined Packaging Line for Efficient Production

In máy đóng bao phân bón today's fast-paced manufacturing environment, efficiency is paramount. Businesses are constantly seeking ways to maximize their production processes and reduce costs. One effective solution is the implementation of an advanced packaging line. These systems integrate state-of-the-art technology to automate the entire packaging process, from product placement to sealing and labeling. By reducing manual labor and streamlining operations, automated packaging lines yield significant benefits such as increased production speeds, reduced errors, and improved overall efficiency.

- Furthermore, automated packaging lines often offer enhanced product protection.

- Through advanced sensors and robotics, these systems can ensure that products are packaged securely and accurately, minimizing damage during transport.

- Therefore, businesses can improve customer satisfaction and reduce product returns.

Refined Packaging with Intelligent Scale Integration

The packaging industry is undergoing a dramatic transformation, driven by the demand for responsible solutions and increasingly efficient operations. Modernized packaging plays a essential role in this evolution, with intelligent scale integration at its foundation. This cutting-edge approach empowers manufacturers to enhance their packaging processes, resulting in {costsavings, optimized efficiency, and a lowered environmental impact.

- Sophisticated scales integrated into the packaging system provide instantaneous data on package mass, enabling precise distribution.

- Programmable adjustments based on this feedback ensure consistent filling accuracy, minimizing excess and optimizing resource utilization.

- The integration of IoT devices further enhances the capabilities of intelligent scale systems, enabling {real-time monitoring and tracking of packaging performance.

Additionally, this technology can be leveraged to {collect valuable data on consumer preferences, enabling manufacturers to adjust their packaging strategies for {increased customer satisfaction and market competitiveness.

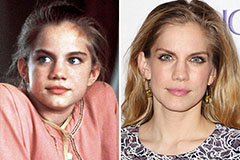

Anna Chlumsky Then & Now!

Anna Chlumsky Then & Now! Kelly McGillis Then & Now!

Kelly McGillis Then & Now! Amanda Bearse Then & Now!

Amanda Bearse Then & Now! Charlie Korsmo Then & Now!

Charlie Korsmo Then & Now! Christy Canyon Then & Now!

Christy Canyon Then & Now!